-

Avoid Pitfalls in Custom Plastic Token Production | Expert Guide

You’ve invested time and money into designing the perfect custom plastic tokens for your business—whether they’re for loyalty programs, gaming, or promotions. But what happens when the delivered batch has inconsistent colors, rough edges, or prints that scratch off? These common pitfalls don’t j...Read more -

Plastic Material Guide for Custom Tokens & Coins | DTG TECH

Choosing the right plastic for your custom plastic tokens or plastic custom coins is one of the most critical decisions you’ll make. It directly impacts the look, feel, durability, safety, and, ultimately, the cost of your project. With so many options—ABS, Acrylic, Polypropylene—it’...Read more -

Material Selection & Market Trends in Acrylic Wine Drinkware

Material Selection & Market Trends in Acrylic Wine Drinkware Choosing the right material for acrylic wine glasses and drinkware is more than an aesthetic decision—it directly impacts product durability, user experience, and profitability. Understanding material properties, market trends, and ...Read more -

Custom Acrylic Wine Glasses Solutions for Hotels, Bars & Events

Custom Acrylic Wine Glasses & Industry Applications For brands and businesses, customization is no longer a luxury—it’s a strategic necessity. Custom acrylic wine glasses and drinkware allow companies to enhance brand visibility, create a cohesive customer experience, and streamline operation...Read more -

Professional Production & Technology Showcase for Acrylic Wine Drinkware

Professional Production & Technology Showcase for Acrylic Wine Drinkware In today’s competitive market, every detail in the production of acrylic wine glasses and drinkware directly affects your profitability and brand reputation. Understanding professional production processes, from raw mate...Read more -

From Prototype to Production: A Case Study on Seamless Manufacturing with DTG

The theoretical benefits of plastic prototype manufacturing are clear: validate designs, reduce risk, and save costs. But how do these principles translate into a real-world success story? This case study details our collaboration with “MediTech Innovations” (a fictional name for a re...Read more -

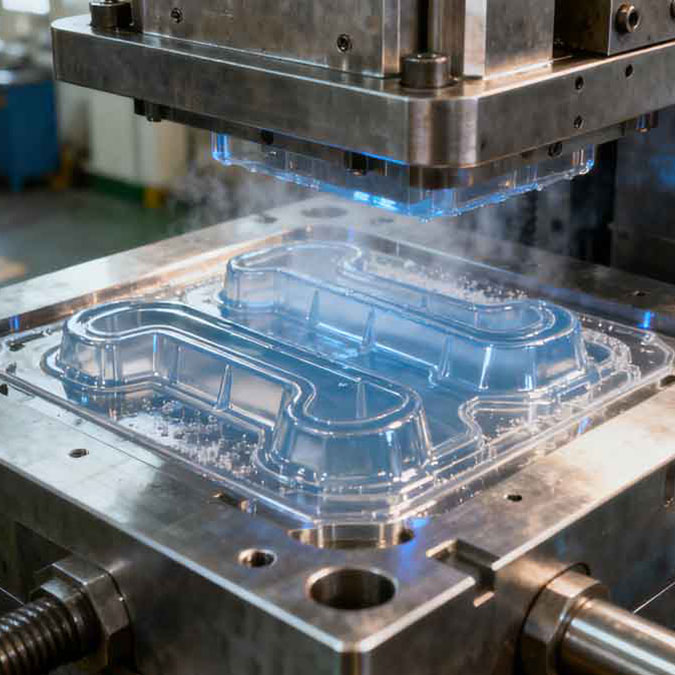

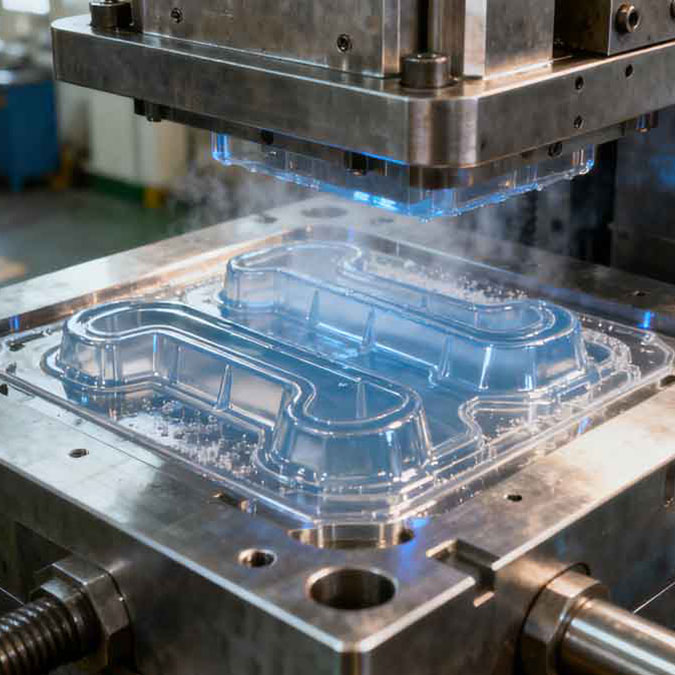

Low-Volume Injection Molding: The Ultimate Guide for Pre-Production Prototypes

When your product development cycle reaches the stage where you need dozens, hundreds, or even thousands of high-fidelity parts, traditional prototyping methods like 3D printing and CNC machining begin to show their limitations. This is where Low-Volume Injection Molding emerges as the dominant s...Read more -

The Cost of Plastic Prototypes: A Detailed Breakdown of Pricing Factors

One of the most common questions in product development is, “How much will a plastic prototype cost?” The answer is rarely simple, as the price is not a single number but the result of a complex interplay of factors. Understanding these cost drivers in plastic prototype manufacturing ...Read more -

Selecting Materials for Plastic Prototypes: A Guide to Engineering-Grade Plastics

In plastic prototype manufacturing, the material you choose is not just about color or feel—it’s about performance. The right material ensures your prototype accurately simulates how the final product will behave, from withstanding impact to resisting chemicals or bearing a load. While 3D p...Read more -

Understanding Plastic Prototype Manufacturing Processes: 3D Printing, CNC Machining, and Injection Molding

When embarking on the journey of creating a new plastic product, selecting the right plastic prototype manufacturing process is the most critical decision you’ll face. This choice directly impacts your timeline, budget, and the fidelity of your design validation. While 3D printing often com...Read more -

The Cost-Efficiency and Flexibility of Low-Volume Injection Molding for Small Runs

Low Volume Injection Molding is a manufacturing solution that allows companies to produce high-quality plastic parts in smaller quantities, making it a perfect choice for small runs, prototypes, and custom parts. This method provides companies with the ability to test new designs, experiment with...Read more -

Low-Volume Injection Molding: Speed and Precision for Custom Manufacturing

In the fast-paced world of product manufacturing, businesses need solutions that provide speed, precision, and flexibility. Low Volume Injection Molding offers all of these advantages, making it an ideal choice for companies needing small-batch production or prototypes. The process involves injec...Read more

Send your message to us:

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur