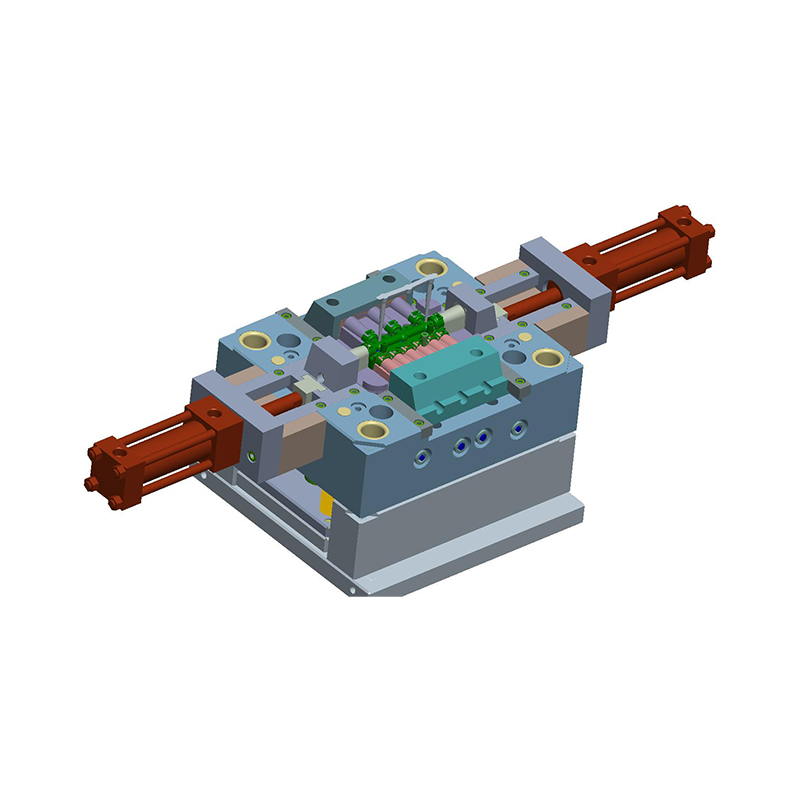

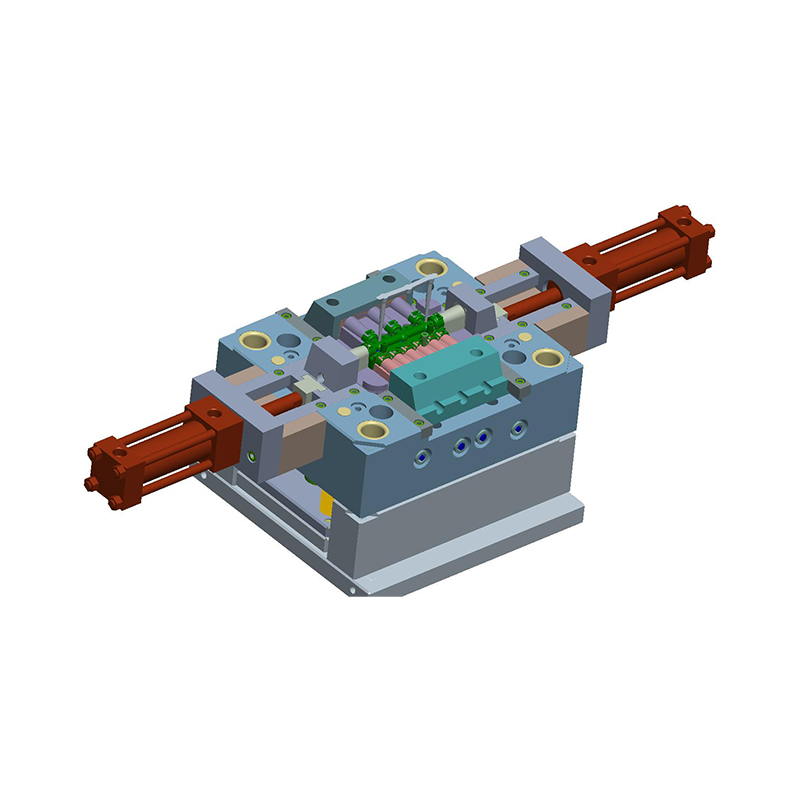

High reputation Plastic Injection Molding - China Professional Customized Plastic Injection Mould For Car Central Control Panel – DTG Detail:

In a word, that is a tool, which can be used to produce plastic products. The mass production cost would cheaper than rapid prototype mass production.

Injection molding is a method to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them. The method is suitable for the mass production of products with complicated shapes, and takes a large part in the area of plastic processing.

A small, single cavity plastic injection mold usually costs between $2,000 and $5,000. Very large or complex molds may cost more, usually the mold we’ve done cost average level is about $ 8000.

Injection molding is cheaper than 3D printing if you produce more than 100 parts. While the cost per unit using 3D printing stays relatively unchanged, the price for injection molding becomes dramatically better the more pieces you manufacture with your mold.

Molds are generally made from steel or aluminum and are precision-machined to form their specific features. A liquid material is fed into a heated barrel, mixed, and fed into the mold’s cavity, eventually cooling and hardening to the mold’s configuration. … Tool steel is the most common material used in mold making.

|

DTG Mould Trade Process |

|

|

Quote |

According to sample, drawing and specific requirement. |

|

Discussion |

Mold material, cavity number, price, runner, payment, etc. |

|

S/C Signature |

Approval for all the items |

|

Advance |

Pay 50% by T/T |

|

Product Design Checking |

We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

|

Mould Design |

We make mould design on the basis of confirmed product design, and send to customer for confirmation. |

|

Mold Tooling |

We start to make mold after mold design confirmed |

|

Mold Processing |

Send report to customer once each week |

|

Mold Testing |

Send trial samples and try-out report to customer for confirmation |

|

Mold Modification |

According to customer’s feedback |

|

Balance settlement |

50% by T/T after the customer approved the trial sample and mould quality. |

|

Delivery |

Delivery by sea or air. The forwarder can be designated by your side. |

Sale Services

Pre-sale:

Our company provide good salesman for professional and promptly communication.

In-sale:

We have strong designer teams, will support customer R&D, If the customer send us samples, we can make product drawing and do the modification as per customer request and send to customer for approval. Also we will accord our experience and knowledge to provide customers our technological suggestions.

After-sale:

If our product have quality problem during our guarantee period, we will send you free for replace the broken piece; also if you have any issue in using our moulds, we provide you professional communication.

Other Services

We make the commitment of service as below:

1.Lead time: 30-50 working days

2.Design period: 1-5 working days

3.Email reply: within 24 hours

4.Quotation: within 2 working days

5.Customer complaints: reply within 12 hours

6.Phone call service: 24H/7D/365D

7.Spare parts: 30%, 50%, 100%, according to specific requirement

8.Free sample: according to specific requirement

We guarantee to provide the best and quick mold service for customers!

|

1 |

Best design,competitive price |

|

2 |

20 years rich experience worker |

|

3 |

Professional in design & making plastic mould |

|

4 |

One stop solution |

|

5 |

On time delivery |

|

6 |

Best after-sale service |

|

7 |

Specialized in kinds of plastic injection molds. |

DTG–Your reliable plastic mould and prototype supplier!

Product detail pictures:

Related Product Guide:

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for High reputation Plastic Injection Molding - China Professional Customized Plastic Injection Mould For Car Central Control Panel – DTG, The product will supply to all over the world, such as: USA, Houston, Belgium, Corporate goal: Customers' satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards reasonable prices, efficient production time and good after-sales service as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.

Send your message to us:

-

PriceList for Automatic Mould - Customized Ano...

-

2021 China New Design Plastic Overmolding - O...

-

Chinese Professional Plastic Injection Mold Par...

-

High reputation Tv Mould - Customized PU8150 P...

-

Excellent quality Custom Plastic Injection Mold...

-

OEM Manufacturer Injection Machine Parts - Cus...