Well-run devices, expert profits group, and better after-sales companies; We have been also a unified huge family, everybody keep on with the organization worth “unification, determination, tolerance” for Factory making China Precision Custom Die Tooling Manufacturer, Plastic Mould, Plastic Precision Mould, Injection Mould, On account of superior quality and competitive selling price , we’re going to be the current market leader, be sure to don’t wait to contact us by mobile phone or email, in case you are fascinated in any of our products.

Well-run devices, expert profits group, and better after-sales companies; We have been also a unified huge family, everybody keep on with the organization worth “unification, determination, tolerance” for China Plastic Precision Injection Mould, Plastic Injection Mould, Now we have many years’ experience in hair product production, and our strict QC Team and skilled workers will ensure that we offer you top hair items with the best hair quality and workmanship. You will get successful business if you choose to cooperate with such a professional manufacturer. Welcome your order cooperation!

Hot runners use a screw nozzle that is fed by a barrel using a pump, while cold runners use a closed, thermoset mold. The primary task of any injection runner system is to direct the material flow from the sprue to the mold cavities. The system requires additional pressure to push the material through the runner.

A hot runner makes it easier for a molding machine to inject plastic into a mould cavity. A hot runner increases the capability of a molding machine. It reduces the plastic flow length so a molder can save material by making thinner and lighter parts

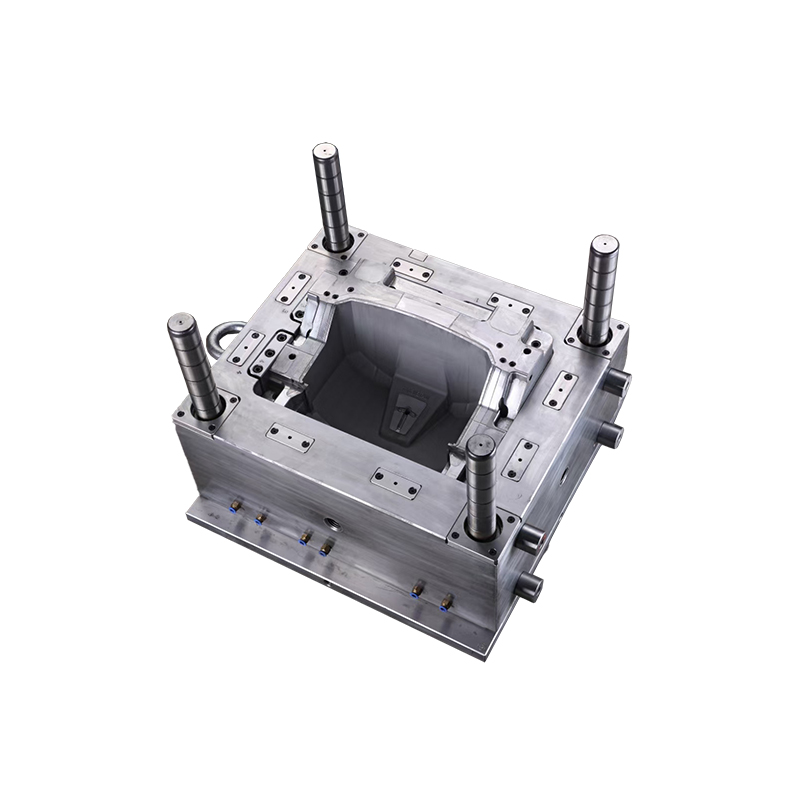

The mold is designed with AB board structure and ejected by ejector pin. It can be automated production. The hot runner dispensing and feeding method can shorten the injection molding cycle and save the plastic material of the runner, thereby reducing costs, improving product quality and reducing waste. During the molding process of the hot runner mold, the temperature of the plastic melt is accurately controlled in the runner system. Elimination of follow-up procedures is conducive to production automation. Expand the application of injection molding technology.

Well-run devices, expert profits group, and better after-sales companies; We have been also a unified huge family, everybody keep on with the organization worth “unification, determination, tolerance” for Factory making China Precision Custom Die Tooling Manufacturer, Plastic Mould, Plastic Precision Mould, Injection Mould, On account of superior quality and competitive selling price , we’re going to be the current market leader, be sure to don’t wait to contact us by mobile phone or email, in case you are fascinated in any of our products.

Factory making China Plastic Precision Injection Mould, Plastic Injection Mould, Now we have many years’ experience in hair product production, and our strict QC Team and skilled workers will ensure that we offer you top hair items with the best hair quality and workmanship. You will get successful business if you choose to cooperate with such a professional manufacturer. Welcome your order cooperation!

Send your message to us:

-

Super Lowest Price China Fasteners F436 DIN125A...

-

Good quality China Customized Car Motor Gear ...

-

Chinese wholesale China High Quality Blow Moldi...

-

Good quality China Customized Car Motor Gear ...

-

Quality Inspection for China Aluminum Lampshade...

-

Renewable Design for Design Mold Rack Shell ABS...