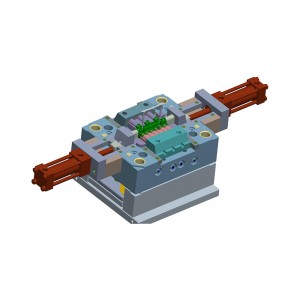

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for Renewable Design for Design Mold Rack Shell ABS Iike Medical Device Silicon Molds Rapid Prototype, We warmly welcome domestic and abroad clients send inquiry to us ,we’ve got 24hours performing workforce! Anytime anywhere we have been still here being your partner.

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for , Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer’s demand, all of our goods have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

3D printing, also known as additive manufacturing, is a method of creating a three dimensional object layer-by-layer using a computer created design. 3D printing is an additive process whereby layers of material are built up to create a 3D part.

3D printed parts are definitely strong enough to be used to make common plastic items that can withstand great amounts of impact and even heat. For the most part, ABS tends to be much more durable, though it does have a much lower tensile strength than PLA.

Limited Materials. While 3D Printing can create items in a selection of plastics and metals the available selection of raw materials is not exhaustive. …

Restricted Build Size. …

Post Processing. …

Large Volumes. …

Part Structure. …

Reduction in Manufacturing Jobs. …

Design Inaccuracies. …

Copyright Issues.Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for Renewable Design for Design Mold Rack Shell ABS Iike Medical Device Silicon Molds Rapid Prototype, We warmly welcome domestic and abroad clients send inquiry to us ,we’ve got 24hours performing workforce! Anytime anywhere we have been still here being your partner.

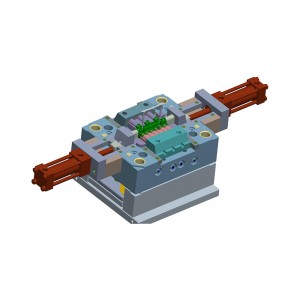

Renewable Design for , Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer’s demand, all of our goods have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

Send your message to us:

-

One of Hottest for China Custom Round Cover Pla...

-

Factory Cheap Hot China Plastic Injection Junc...

-

New Delivery for China Customized Plastic High ...

-

OEM Manufacturer China Custom Cheap Plastic Aut...

-

China Factory Supply Prototype with Plastic In...

-

Personlized Products China Factory Plastic Prod...