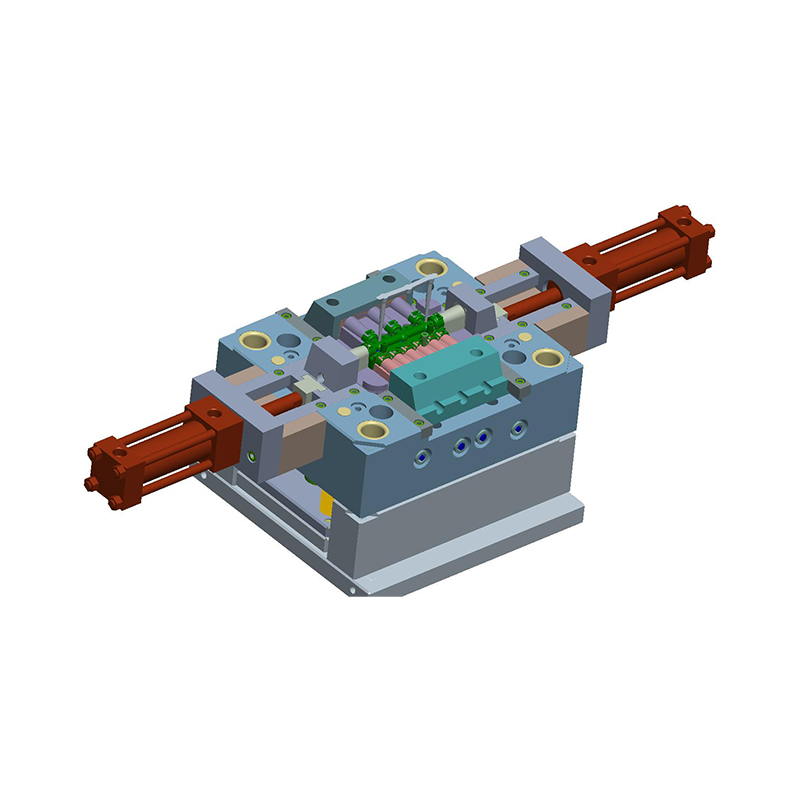

New Fashion Design for Plastic Home Appliance Mould - Customized PU8150 Plastic Parts Made By Vacuum casting – DTG Detail:

Technologies: vacuum casting

Material: ABS like – PU 8150

Finished: Painting matte white

Production time: 5-8 days

Let’s talk some more details about vacuum casting.

This is a casting process for elastomers which uses a vacuum to draw any liquid material into the mold. Vacuum casting is used when air entrapment is a problem with the mold. Additionally, the process can be used when there are intricate details and undercuts on the mold.

Rubber – high flexibility.

ABS – high rigidity and strength.

Polypropylene and HDPR – high elasticity.

Polyamide and glass filled nylon – high rigidity.

High precision, fine detail: the silicone mold makes it possible to obtain parts totally faithful to the original model, even with the most complex geometries. … Prices and deadlines: the use of silicone for the mold allows a reduction of costs compared to an aluminum or steel molds.

Production Restriction: Vacuum casting is born for low volume production. The silicone mold has a short lifespan. It can produce as many as 50 parts.

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of your crucial certifications of its market for New Fashion Design for Plastic Home Appliance Mould - Customized PU8150 Plastic Parts Made By Vacuum casting – DTG, The product will supply to all over the world, such as: Brazil , Croatia , Nepal , When you are keen on any of our goods following you view our product list, be sure to feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we're able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our products by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.

Send your message to us:

-

China wholesale Elevator Mould - CNC Machining...

-

2021 High quality Car Mould - Die Casting Alum...

-

Fast delivery Injection Molded Shell - OEM hi...

-

Reasonable price Custom Plastic Injection Moldi...

-

Hot New Products Customized Plastic Enclosure -...

-

Super Lowest Price Metal Processing Machine Par...