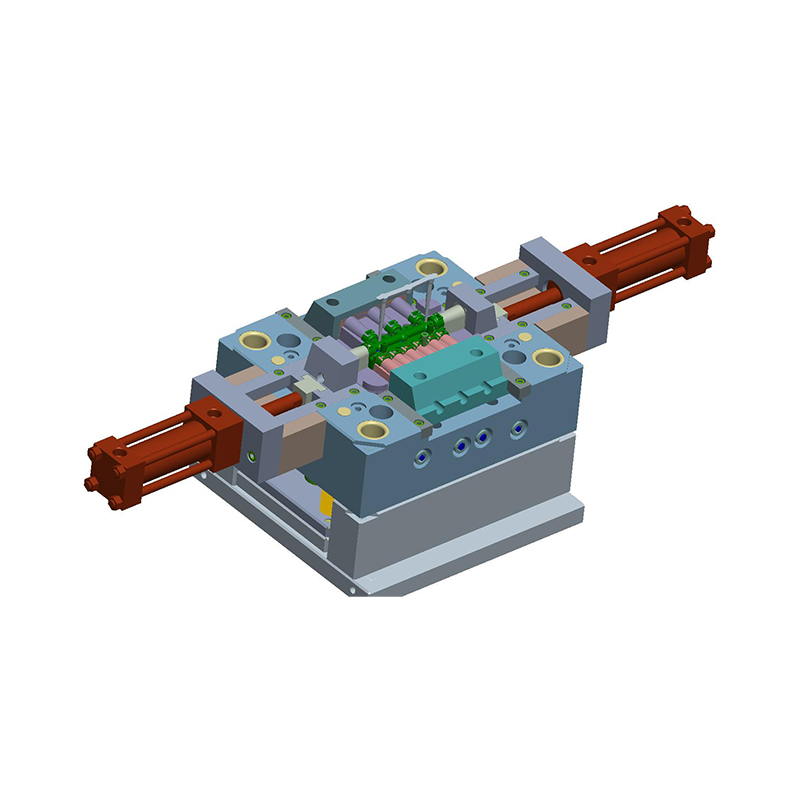

Low price for Precision Cnc Machining Parts - OEM PC+PP Car Air Conditioning Control Panel Made By Plastic Injection Mould – DTG Detail:

Double color moulding is the one available process for managing product moulding with two different materials and colors, using simultaneous molding processes in the same injection machine to output a single unit.

Why we choose Polypropylene+Polycarbonate to produce this air conditional control panel ?

From material properties point: PC material has excellent electrical insulation, lengthening, dimensional stability, chemical resistance, heat resistance and cold resistance, and also has self-extinguishing properties, and also has the advantages of cool non-toxic; strength can meet whole body shell products, suitable for industrial product mass production.

The light transmission effect and pattern of the white part make it clear to use. The PC material is added with 0.025% silver powder to bring out its uniqueness. The only innovative automotive air-conditioning control panel in the industry is formed by double color injection molds.

Last but no least, let us talk about the product features:

It is worthy mentioned that the product has a unique appearance design. The functions of the 5 boss buttons are distinct, simple and generous. The design of the concave and convex step structure can make the product deformation very small, and there is almost no deformation after moulding, and the user can easily find the required boss button.

Except the double color mould mentioned above, we can also do single color mould, rubber coated mold, etc. We have a wide range business scope.

|

DTG Mould Trade Process |

|

|

Quote |

According to sample, drawing and specific requirement. |

|

Discussion |

Mold material, cavity number, price, runner, payment, etc. |

|

S/C Signature |

Approval for all the items |

|

Advance |

Pay 50% by T/T |

|

Product Design Checking |

We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

|

Mould Design |

We make mould design on the basis of confirmed product design, and send to customer for confirmation. |

|

Mold Tooling |

We start to make mold after mold design confirmed |

|

Mold Processing |

Send report to customer once each week |

|

Mold Testing |

Send trial samples and try-out report to customer for confirmation |

|

Mold Modification |

According to customer’s feedback |

|

Balance settlement |

50% by T/T after the customer approved the trial sample and mould quality. |

|

Delivery |

Delivery by sea or air. The forwarder can be designated by your side. |

Sale Services

Pre-sale:

Our company provide good salesman for professional and promptly communication.

In-sale:

We have strong designer teams, will support customer R&D, If the customer send us samples, we can make product drawing and do the modification as per customer request and send to customer for approval. Also we will accord our experience and knowledge to provide customers our technological suggestions.

After-sale:

If our product have quality problem during our guarantee period, we will send you free for replace the broken piece; also if you have any issue in using our moulds, we provide you professional communication.

Other Services

We make the commitment of service as below:

1.Lead time: 30-50 working days

2.Design period: 1-5 working days

3.Email reply: within 24 hours

4.Quotation: within 2 working days

5.Customer complaints: reply within 12 hours

6.Phone call service: 24H/7D/365D

7.Spare parts: 30%, 50%, 100%, according to specific requirement

8.Free sample: according to specific requirement

We guarantee to provide the best and quick mold service for customers!

|

1 |

Best design,competitive price |

|

2 |

20 years rich experience worker |

|

3 |

Professional in design & making plastic mould |

|

4 |

One stop solution |

|

5 |

On time delivery |

|

6 |

Best after-sale service |

|

7 |

Specialized in kinds of plastic injection molds. |

DTG–Your reliable plastic mould and prototype supplier!

Product detail pictures:

Related Product Guide:

Our goal is to satisfy our customers by offering golden service, good price and high quality for Low price for Precision Cnc Machining Parts - OEM PC+PP Car Air Conditioning Control Panel Made By Plastic Injection Mould – DTG, The product will supply to all over the world, such as: Japan, Denmark, United States, Our company has built stable business relationships with many well-known domestic companies as well as oversea customers. With the goal of providing high quality products to customers at low cots, we've been committed to improving its capacities in research, development, manufacturing and management. We have honored to receive recognition from our customers. Till now we have now passed ISO9001 in 2005 and ISO/TS16949 in 2008. Enterprises of quality of survival, the credibility of development for the purpose, sincerely welcome domestic and foreign businessmen to visit to discuss cooperation.

We have been looking for a professional and responsible supplier, and now we find it.